The Association for Manufacturing Excellence (AME), is a not-for-profit organization founded in 1985 dedicated to helping companies with continuous improvement and their pursuit of excellence. Whether looking to learn about lean manufacturing or one of the continuous improvement tools like value stream mapping, kaizen, lean supply chain, lean new product development, lean accounting, or leadership of lean transformation you've come to the right place.

AME is practitioner based which means our events and workshops are hands-on and taught by others who have ñbeen thereî and want to share their experiences. Visit our site to obtain more information on all of our educational opportunities or join AME and start receiving the many benefits of membership including our award-winning Target magazine.

- Company Name:The Association For Manufacturing Excellence

(View Trends)

-

Headquarters: (View Map)Rolling Meadows, IL, United States

-

Nonprofit Organization Management

-

10 - 50 employees

- 1409025 Global Rank

- 335267 United States

-

Search73.20%

-

Direct25.56%

-

Mail1.00%

-

Social0.24%

-

Display0.00%

-

Referrals0.00%

- United States 58.4%

- Industrial Goods and Services

- 5 SDKs

- 4.93 Avg. Rating

- 12 Total reviews

- App Url: https://itunes.apple.com/app/assocation-for-manufacturing-excellence/id952590820

- App Support: http://ame.org

- Genre: Business

- Bundle ID: org.ame.AME

- App Size: 2.62 M

- Version: 1.36

- Release Date: September 20th, 2016

- Update Date: April 18th, 2020

Description:

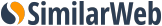

The Association for Manufacturing Excellence offers the AME Lean Sensei to anyone interested in benchmarking their organization against distinguished AME Excellence Award recipient companies. AME Excellence Award recipients operate at exceptional levels of performance, setting the bar high for achieving success in the search for operational excellence. If you are interested in joining this distinguished group of recipients, the AME Lean Sensei will help you see if you’re ready to apply. If you’re not interested in applying for the AME Excellence Award, the AME Lean Sensei is still a valuable tool to help your organization identify potential areas of focus and improve the way you improve.

How to use the AME Lean Sensei:

Have 5 to 10 key staff members or key knowledgeable associates come together in one room. Include people who have little to do with direct responsibilities for your improvement program activities. Discuss each question and arrive at a letter grade for each answer. The AME Lean Sensei should be used as a systematic process for your team to improve. It is not a survey to be given to all employees but should be used by a team that has some familiarity with basic lean principles.

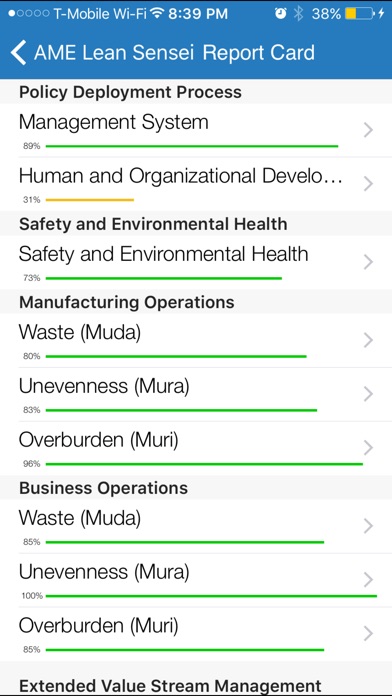

A+ = Best in class – World-class benchmark

A = Excellent - Sustainable with great results

B = Good results – Definitely going in the right direction

C = On the journey - Some process gaps but striving for improvement

D = More gaps than achievements – Definite area for improvement

F = No achievements in this area – No process documented or followed

Once you select a letter grade for every question, AME Lean Sensei will populate the dashboard and report card automatically. With this information, you can easily see your improvement maturity strengths and weaknesses. The letter scoring is the easy part of the AME Lean Sensei. To truly get the most benefit from the tool you must take the next step. You will see that each question has an area to document proof (for grades B or greater) and an area to document gaps (for grades C or below). The overall score is not important; there is no final destination relative to improvement practices.

How to get the most from this tool :

The best senseis—or teachers— always ask thought-provoking questions and do not give mere answers. The questions asked by the AME Lean Sensei will help you think about how to become best-in- class at your site or facility.

As you answer the AME Lean Sensei, ask yourselves:

- How can we prove this in writing?

- How can we prove this visually?

- Do we have any external benchmarks of excellence for comparative purposes?

- What gaps do we have for each question?

Have we reached the level of excellence necessary to apply for the AME Excellence Award and, if so, how can we engage the entire company in that process?

Sort by

Al Preslicka

Queen of Lean

What’s not to love

VP CI Healthcare

Great Tool for Free

Lean Flow Guy

Culture As Strong As Weakest Ingredient

241016

Believer

QofLean

Great tool to check your lean progress

They are headquartered at Rolling Meadows, IL, United States, and have 2 advertising & marketing contacts listed on Kochava. The Association For Manufacturing Excellence works with Advertising technology companies such as DoubleClick.Net, Twitter Ads, Facebook Custom Audiences, Simpli.fi, eXelate, ContextWeb, Adobe Audience Manager Sync, Magnetic, AppNexus, The Trade Desk, Openads/OpenX, Yahoo Small Business, Turn, Pubmatic, Rubicon Project, Aggregate Knowledge, BlueKai DMP, Index Exchange, Tapad, VigLink, BlueKai, DemDex, IponWeb BidSwitch, Advertising.com, X Plus One, Burst Media, RUN Ads, Google Remarketing, Eyeota, Dstillery, Beeswax, Drawbridge, Narrative, LinkedIn Ads, FLoC Opt-Out, FLoC, comScore Activation.

Aerospace BB